This white paper delves into the dynamic journey of manufacturing rotationally molded polyethylene tanks over the past four decades. Unlike tanks crafted from traditional materials such as mild steel, stainless steel, and fiberglass, the realm of rotationally molded polyethylene tanks is a relatively youthful domain.

This white paper delves into the dynamic journey of manufacturing rotationally molded polyethylene tanks over the past four decades. Unlike tanks crafted from traditional materials such as mild steel, stainless steel, and fiberglass, the realm of rotationally molded polyethylene tanks is a relatively youthful domain.

Exploring the origins of ASTM wall thickness calculations, we uncover their pivotal role in shaping the landscape of manufacturing rotationally molded polyethylene tanks today.

If you’re intrigued by the advancements in molding technologies that have revolutionized the production of consistently high-quality parts, we invite you to delve deeper into the evolution of manufacturing rotationally molded tanks by downloading our white paper for a comprehensive exploration.

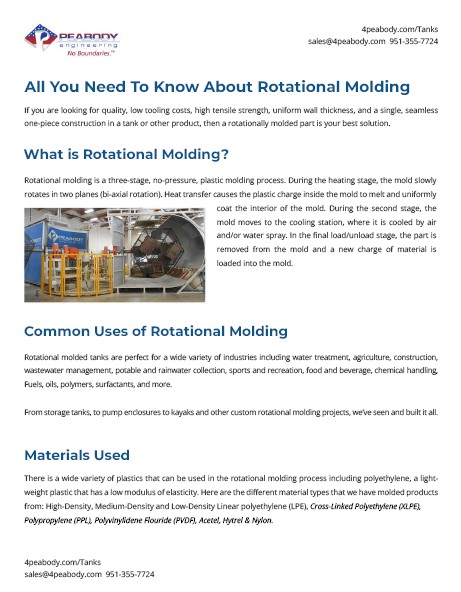

If you are looking for quality, low tooling costs, high tensile strength, uniform wall thickness, and a single, seamless one-piece construction in a tank or other product, then a rotationally molded part is your best solution.

If you are looking for quality, low tooling costs, high tensile strength, uniform wall thickness, and a single, seamless one-piece construction in a tank or other product, then a rotationally molded part is your best solution.

About 35 years ago, Peabody Engineering did a study in cooperation with California State University Long Beach Engineering Structures Lab to design a viable seismic restraint system for our polyethylene tanks.

About 35 years ago, Peabody Engineering did a study in cooperation with California State University Long Beach Engineering Structures Lab to design a viable seismic restraint system for our polyethylene tanks.

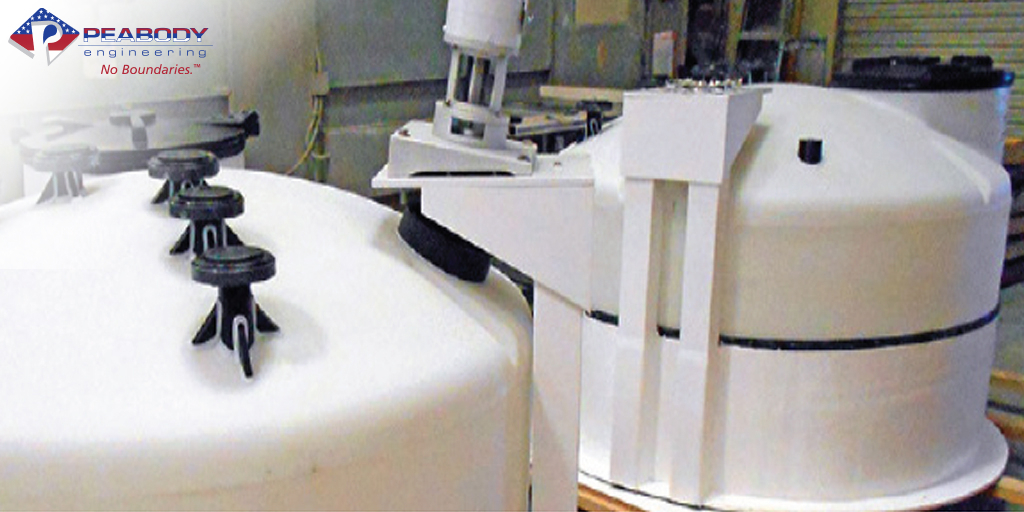

With more than 40 years in the plastic tank business, you would be hard pressed to find an application we haven’t seen before. When it comes to building polyethylene tanks for custom applications, there are always unique design considerations. Our whitepaper includes important factors when configuring and specifying a special application storage tank.

With more than 40 years in the plastic tank business, you would be hard pressed to find an application we haven’t seen before. When it comes to building polyethylene tanks for custom applications, there are always unique design considerations. Our whitepaper includes important factors when configuring and specifying a special application storage tank.

When it comes to maximizing the life cycle of your storage tank assets, and your ROI, it’s natural to choose the most cost-effective, durable construction material for your application. For those reasons and more, polyethylene for commercial storage tanks is ideal for applications storing a wide range of liquids. But what is the expected life cycle of a polyethylene tank? This white paper,

When it comes to maximizing the life cycle of your storage tank assets, and your ROI, it’s natural to choose the most cost-effective, durable construction material for your application. For those reasons and more, polyethylene for commercial storage tanks is ideal for applications storing a wide range of liquids. But what is the expected life cycle of a polyethylene tank? This white paper,