Best Practices for Shipping & Packing of Polyethylene Tanks

When investing in a polyethylene tank, ensuring it reaches your facility in perfect condition is critical. At Peabody Engineering, we take every precaution to protect our tanks during transit, but proper handling upon delivery is equally important. This guide outlines best practices for shipping, receiving, and unloading polyethylene tanks of all sizes.

When investing in a polyethylene tank, ensuring it reaches your facility in perfect condition is critical. At Peabody Engineering, we take every precaution to protect our tanks during transit, but proper handling upon delivery is equally important. This guide outlines best practices for shipping, receiving, and unloading polyethylene tanks of all sizes.

Shipping Methods by Tank Size

Small Tanks (5 to 65 Gallons)

For smaller tanks, standard shipping methods like UPS and FedEx are used. When shipping multiple tanks, they are palletized, strapped, and wrapped in polyethylene film for added protection. Accessories are placed inside the tank to prevent damage, and these shipments can typically be unloaded by hand, pallet jack, or forklift.

Medium-Sized Tanks (70 to 1500 Gallons)

Larger tanks exceed small package shipping limits and are transported via common or contract carriers. These tanks are securely palletized and wrapped to prevent damage. Tanks over 48 inches in diameter are placed on custom-built pallets, with additional protection for welded nozzles and fittings. Unloading typically requires a pallet jack or forklift.

Large Tanks (Over 1500 Gallons)

Larger polyethylene tanks are often customized with welded nozzles, ladders, and other components. They require specialized handling, often shipped via dedicated trucks as “wide loads.” These tanks are typically laid on their side and must be handled carefully during unloading. Peabody Engineering provides a guide on safe tank unloading and installation upon request.

Receiving and Inspecting Your Tank

Upon delivery, conduct a thorough inspection before signing the bill of lading:

✅ Check for damage – Examine both the exterior and interior of the tank for signs of impact or loose parts.

✅ Verify shipment contents – Ensure all items listed on the bill of lading are accounted for, including any accessories.

✅ Document issues immediately – If damage is noted, take photos and document it on the receiving paperwork before accepting the shipment.

Failure to note damages upon delivery can result in difficulty filing a claim with the freight company.

Proper Offloading Procedures

To prevent damage during unloading:

- Do not roll tanks off the truck – Rolling can damage fittings and accessories.

- Use the correct equipment – Large tanks should be offloaded with a forklift or crane.

- Account for environmental factors – Wind and uneven terrain can make handling more challenging.

Need Assistance?

Peabody Engineering has over 40 years of experience in polyethylene tank manufacturing and logistics. If you encounter issues or have questions about handling your tank, our team is ready to assist. Contact us at 1-800-4-PEABODY for expert support.

Fill out form to Download this white paper to serve as a reference to understand what to expect when receiving your tanks.

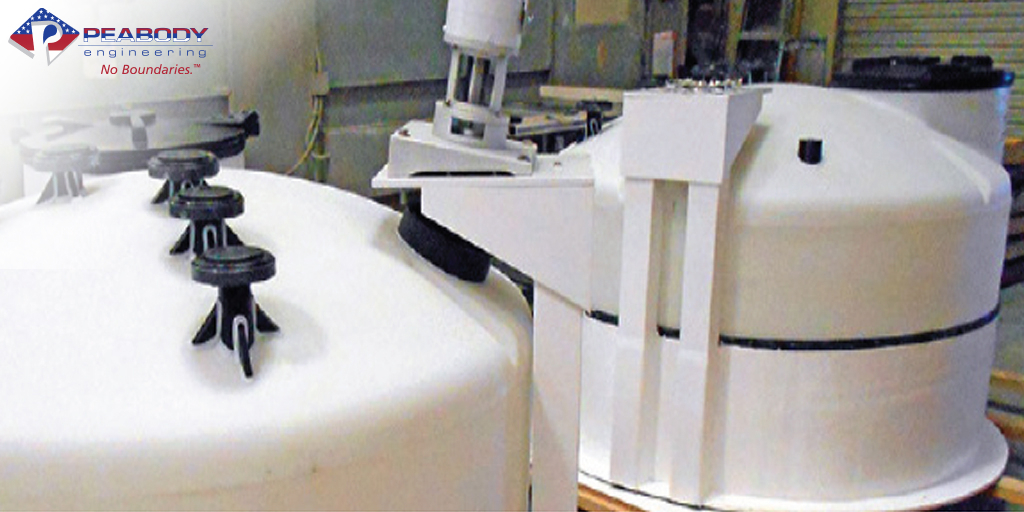

Engineered Polyethylene Tank Systems – Components

Engineered Polyethylene Tank Systems – Components

This white paper delves into the dynamic journey of manufacturing rotationally molded polyethylene tanks over the past four decades. Unlike tanks crafted from traditional materials such as mild steel, stainless steel, and fiberglass, the realm of rotationally molded polyethylene tanks is a relatively youthful domain.

This white paper delves into the dynamic journey of manufacturing rotationally molded polyethylene tanks over the past four decades. Unlike tanks crafted from traditional materials such as mild steel, stainless steel, and fiberglass, the realm of rotationally molded polyethylene tanks is a relatively youthful domain.

If you are looking for quality, low tooling costs, high tensile strength, uniform wall thickness, and a single, seamless one-piece construction in a tank or other product, then a rotationally molded part is your best solution.

If you are looking for quality, low tooling costs, high tensile strength, uniform wall thickness, and a single, seamless one-piece construction in a tank or other product, then a rotationally molded part is your best solution.

About 35 years ago, Peabody Engineering did a study in cooperation with California State University Long Beach Engineering Structures Lab to design a viable seismic restraint system for our polyethylene tanks.

About 35 years ago, Peabody Engineering did a study in cooperation with California State University Long Beach Engineering Structures Lab to design a viable seismic restraint system for our polyethylene tanks.

With more than 40 years in the plastic tank business, you would be hard pressed to find an application we haven’t seen before. When it comes to building polyethylene tanks for custom applications, there are always unique design considerations. Our whitepaper includes important factors when configuring and specifying a special application storage tank.

With more than 40 years in the plastic tank business, you would be hard pressed to find an application we haven’t seen before. When it comes to building polyethylene tanks for custom applications, there are always unique design considerations. Our whitepaper includes important factors when configuring and specifying a special application storage tank.

When it comes to maximizing the life cycle of your storage tank assets, and your ROI, it’s natural to choose the most cost-effective, durable construction material for your application. For those reasons and more, polyethylene for commercial storage tanks is ideal for applications storing a wide range of liquids. But what is the expected life cycle of a polyethylene tank? This white paper,

When it comes to maximizing the life cycle of your storage tank assets, and your ROI, it’s natural to choose the most cost-effective, durable construction material for your application. For those reasons and more, polyethylene for commercial storage tanks is ideal for applications storing a wide range of liquids. But what is the expected life cycle of a polyethylene tank? This white paper,